MINE SITE PRESERVATION

Quincy Mine Shaft No. 2, Hancock, Michigan

Champion Mine, Painesdale, Michigan

Cornish Pump Chapin Mine, Iron Mountain, Michigan

Wooden Water Bailing Car on Left, Man Car on Right

Champion Mine Machine Shop

Champion Mine Shaft/Rockhouse No.4

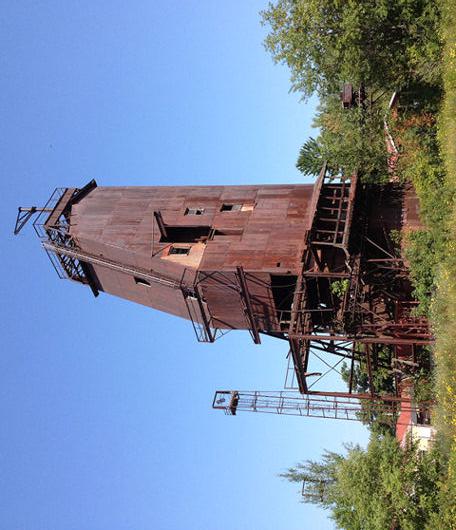

Efforts are presently underway to preserve the Champion Mine No.4 Shaft and Rockhouse located in Painesdale, Michigan. The Champion Mining Co. was organized in 1899 and came under control of the Copper Range Consolidated Co. in 1901. By the 1930's the mine was working the 48th level in #4 shaft, 4,800 ft. from the surface on the incline. This shaft was later extended to the 56th level, approx. 5,500 ft. from the surface on the incline. In 1945, the mine closed to remove equipment from below the 48th level to abandon that section of the mine. In 1948, the mine reopened with work on the 18th level of shaft #4.

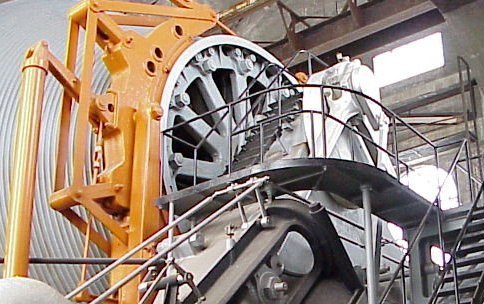

Iron Mountain, Michigan is the home of the Cornish Pumping Engine formerly used in D Shaft of the Chapin Mine. The E.P. Allis Co. largest Cornish Style Pump built in the U.S. standing 54' tall with a 40" diameter flywheel weighing 160 tons and a drive shaft that is 2' in diameter. The pump has a rated capacity of 5,000,000 gallons per day. In 1907 the pump was purchased by the Olicer Iron Mining Co. and re-built at their Ludington Mine, where it operated until 1914 de-watering the Ludington and Hamilton mines, when it was replaced by electric pumps. Mining exhibits surround the pump in the museum building.

40' diameter, 160 ton flywheel

2' diameter drive shaft

Pump Rod

Quincy Mine No. 2 Shaft/Rockhouse

Quincy Mine No.2 Hoist House with Ore Skips Laying in Foreground

Quincy Hoist Braking System

Quincy Mine Shaft No.2 Hoist House with Quincy & Torch Lake Railroad Engines in the Foreground

Quincy Mine Shaft No. 2 Hoist House and Shaft/Rockhouse

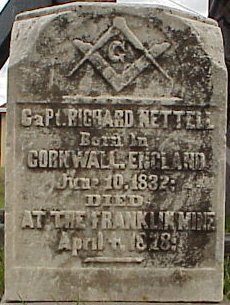

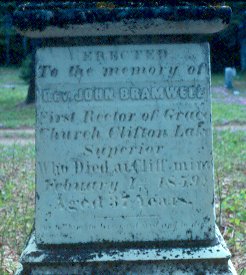

Mine Cemeteries in the Michigan Copper Country

For many decades the old cemeteries associated with copper mines of the Keweenaw Peninsula were neglected and nearly forgotten. In recent years these old cemeteries have been recognized by new generations as the important historical resources that they are and efforts are being made to reclaim them from nature for future generations.

Henry Hart

Killled at Copper Falls Mine

July 15 A.D. 1872

Aged 21 years

Capt. Richard Nettell

Born in Cornwall England

June 10, 1832 Died

AT THE FRANKLIN MINE

April 4, 1878

Rev. John Bramwell

First Rector of Grace

Church of Cifton Lake

Superior

Who died at Cliff Mine

February 1, 1859

Aged 37 Years

JOHN CHELLEW

Who met his death

Jan. 1, 1875

by an accident in

the Cliff Mine

Aged 27 Yrs. 4Ms.

William Jennings

Who Departed this Life

at Cliff Mine

June 23, 1857

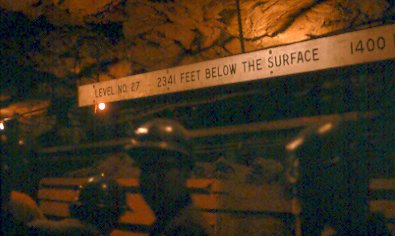

SOUDAN UNDERGROUND MINE STATE PARK

Located in Tower, on the Vermillion Iron Range in northeastern Minnesota,, the former Oliver Iron Mining Co. Soudan Iron Mine has been preserved as a State Park offering underground and above ground tours.

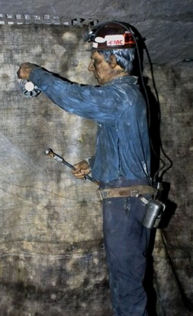

Mucker and ore car display

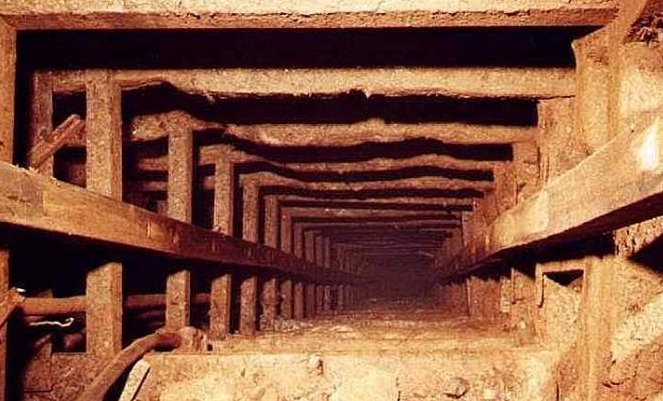

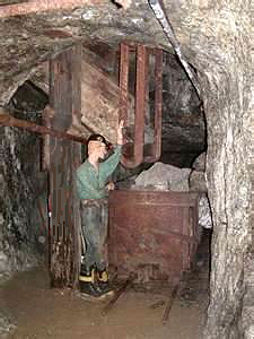

Start of underground tour on the 27th Level

Electric mine "Loco" display

Quincy Mining Co. Dredge NO. 2, Mason, MI

While presently not being preserved, a good candidate for preservation is the Quincy Mining Co. No.2 Dredge at Mason, MI. Built originally in 1913 for the Calumet and Hecla Consolidated Mining Co. for use at their Lake Linden Reclamation Plant. Used to rework stamp sand from the C&H stamp mill, the dredge could process 10,000 tons of stamp sand per day with a 141' suction hose that could work in up to 115' of water. The dredge was bought from C&H in 1951 and used until 1967 to process stamp sand for their Mason Reclamation Plant.

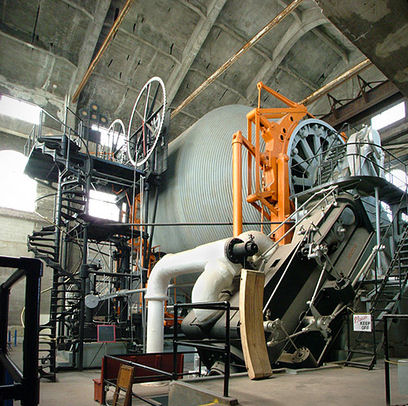

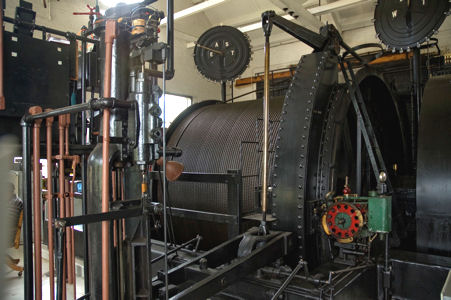

The Quincy Mining Co. was incorporated in 1848 and produced copper from 1851 through 1967, paying uninterrupted dividends from 1867 to 1920. Preserved is the Quincy No. 2 shaft and rockhouse and the No. 2 Hoist, the largest steam powered hoist in the world. Produced by the Nordberg Mfg. Co., the 30' drum held 10,000' of 1 5/8" wire rope and could hoist 10 ton skips at the rate of 3.200' per minute.

The Quincy Mine is one unit of the larger Keweenaw National Historical Park administered by the National Park Service. Underground tours and tours of the hoist house are available, along with a ride on a cog railroad on Quincy Hill.

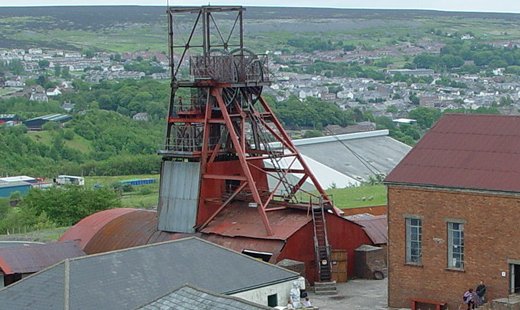

National Coal Mining Museum of England

Located on the A642 halfway between Wakefield and Huddersfield in Yorkshire. Coal Seams at this site were first worked in 1791 and the mine closed in 1985.. The Caphouse Colliery is open for above ground and underground tours. The adjacent Hope Pit Colliery is in the process of being restored.

Caphouse Colliery

Caphouse Colliery Headframe

Mine Lamp Display

Horse Powered Whim

Start of the Underground Tour

Geevor Tin Mine Heritage Center Pendeen, Penzance, Cornwall

Located in the St. Just Mining District of Cornwall, England, the Geevor Tin Mine was allowed to flood in 1991 and was re-opened as a mining heritage center in 1993. Underground tours are given of the older Wheal Mexico Adit on the same property. The entire surface plant is open for tours.

Victory Shaft and Surface Plant Geevor Mine

Underground - Wheal Mexico

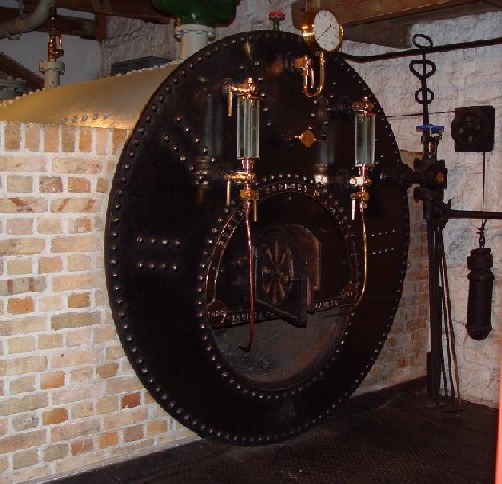

Geevor Duplex Steam Winder

Geevor Electric Winder

Geevor Ball Mill

Geevor Shaker Tables

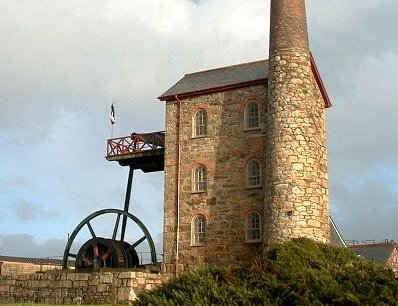

Levant Mine Pendeen, Penzance, Cornwall

Oriiginally an independent mine adjacent to Geevor Mine and later part of the Geevor property, the Levant Mine houses the first steam beam engine preserved at its original working site in 1935. This engine, built by Harvey & Co. of Hale, Cornwall, is now the oldest working beam engine in Cornwall, having been placed in service in 1840 and working until 1930. Tours of the engine house are offered and this engine is impressive to see in steam. This mine is situated on the edge of a high seaside cliff.

Levant Mine - winding engine house to left, pump engine house to right, headframe center

Me standing on the cliff below the Geevor Mine next to the Levant Mine

Cornish Mines & Engines Pool, Redruth, Cornwall

This twin National Trust Property consists of the 1887 beam pump and pump house at the Michell's Shaft and the 90" cylinder beam pump and pump house at the Taylor Shaft of the East Pool Mine. The adjacent sites are open for tours of the surface plant. This property takes in the East Pool and Ager Mine sites.

Michell's Shaft Beam Winding Engine

Beam on Michell's Shaft Engine

National Mining Museum of Wales Big Pit Colliery Blaenavon, Torfaen, Wales

Located in the Northeast corner of the South Wales Coalfield in the Afon Lwyd Valley lies Big Pit Colliery, opened in 1860 and worked until 1980. Surface and underground tours are offered.

Big Pit Headframe

Blacksmith Shop

Me standing at a restored double shaft chain hoist

Rotating coal car dumper

Looking Down Levant Mine Skip Shaft

Botallack Mine Crowns Shaft

One of the most picturesque of all Cornish mining sites it that of the Botalllack Mine. Situated on the very edge of the Cornish Coast, with workings that went out under the sea, this site is now in an arrested state of decay.

Botallack Mine Crowns Shaft

Botallck Mine Crowns Shaft

Michell's Shaft Winding Engine Boiler

Barthell Coal Camp Restoration, Stearns, KY

Dating back to 1902, Barthell was the first of 18 mining camps belonging to the Stearns Coal and Lumber Co. By 1909, Barthell consisted of 41 dwellings, company "Store Number Two" (there were a total of 18), a big motor house, bath house, tipple, school and a post office. Fifteen one and two bedroom houses, the bathhouse, barbershop and doctor's office have been meticulously restored and stocked with period antiques. There is also a display of mining equipment and old vehicles.

Bath House Interior

Coal Company House

Company House Interior

Company School Interior

Mine Portal

East Pool Mine

Portal 31, Lynch, Kentucky

In 1917 the U.S. Coal & Coke Company, a subsidiary of U.S. Steel, constructed the community of Lynch, Kentucky, the world's largest coal camp at that time. The community was built on a portion of the 19,000 acres the company had purchased in southeastern Harlan County, near the Virginia border. The camp's population peaked at about 10,000 persons but the figure varies because of the transient nature of the miners and their families. One thousand company owned structures provided housing for people of 38 nationalities, the most prominent of which were Italian, Spanish, Czech, Polish, English, Welsh, Irish and Scottish. By the 1940s more than 4000 persons were employed above and below ground.

The public buildings were constructed of cut sandstone, and included a company commissary, post office, theater, hotel, hospital, churches, and schools. Many company buildings were built of stone as well, such as the offices, bath house, power plant and lamp house. In the 1920s U.S. Coal & Coke owned the world's largest coal tipple with a capacity of 15,000 tons. On February 12, 1923 the world's record for coal production in a single 9 hour shift was achieved when miners operating 40 shortwall cutting machines produced 12,820 tons of coal that filled 256 railcars.

While considered one of Appalachia's model coal camps due to its' company provided health care, education, churches, housing, social services, wages and benefits and recreation, it was still a closed community where the company controlled all aspects of community life. The company had their own police force and it was used to keep union organizers out of the coal camp and to intimidate miners who attempted to join the union. Throughout the 1920s and well into the 1930s the company, along with many Kentucky coal producers, did everything in their power to prevent unionization. This action by the coal companies and the actions of the miners earned Harlan County the name of "Bloody Harlan"

Today, Portal 31 offers visitors the experience of touring an actual coal mine by rail car. Visitors will don the traditional protective gear of the coal miner as they enjoy animated exhibits demonstrating coal mining methods in a real coal seam. Outside Portal 31 stands a black granite monument, tribute to long time president of the United Mine Workers John L. Lewis and a memorial to U.S. Steel District No.1 miners who died in mining accidents. The site also features a 1920s lamphouse, bathhouse, L&N train depot and coal loading system.

Kentucky's segregated past is seen in this old school

Checking air flow

with an anemometer

Miner loading a horse drawn coal car by hand

Hand loading a electric loco drawn coal car

Quincy Mine Hoist Engine

Sterling Hill Mine Museum - Ogdensburg, NJ

Mining began at the site in 1730, when it was thought to be a copper deposit. King George III of England granted the property to William Alexander, titled Lord Stirling. Stirling sold it to Robert Ogden in 1765. It went through several owners until the various mines were combined into the New Jersey Zinc Company in 1897. The mine closed in 1986 due to a tax dispute with the town, which foreclosed for back taxes in 1988 and auctioned the property to Richard and Robert Hauck. It opened as a museum in August 1990.

The mine was the last working underground mine in New Jersey when it closed in 1986. The museum now offers preserved mine surface structures and outdoor displays of mining equipment, an exhibit hall with mining artifacts, and mineral displays, underground tours and mineral collecting. The mine is also home to the Ellis Astronomical Observatory and the Thomas S. Warren Museum of Fluorescence, with a large display of fluorescent minerals.

In the area of the Sterling Hill mine 357 minerals are known to occur; these make up approximately 10% of the minerals known to science. Thirty-five of these minerals have not been found anywhere else. Ninety-one of the minerals fluoresce.

The Caspian mine, located at Caspian, Michigan, was worked from 1903 through 1937 by the Verona Iron Mining Company, shipping 6.6 million tons of ore from three shafts and five levels to a depth of 539 feet. The Caspian was the second of three mines opened and owned by the Verona Mining Company.The headframe is a 106 foot high steel-framed structure clad in corrugated steel siding.

Today, the Caspian mine is owned by the Iron County Historical Society and is the site of their museum. opened in 1968. It is Upper Michigan's largest local museum and is located on nearly 10 acres of land. It has 26 buildings and over 100 major exhibits and includes 2 special art galleries - the Lee LeBlanc Wildlife Gallery and the Giovanelli Italianate Gallery.

Major exhibits are found in the Main Building, the former Caspian Mine Engine House, and the attached Peterson Mining Hall, the Mining Memorial Hall, Heritage Hall, three galleries in the Cultural Center and the Lee LeBlanc Wildlife Art Gallery. They reflect the multi-ethnic groups who settled in Iron County to work in the major industries of iron mining and logging. Unusual glass dioramas display underground mine work and a diorama consisting of over 100 miniature pieces carved to scale show a logging camp and work in the woods.

Exhibits are also found in the Outdoor Complex - The Homestead composed of log buildings, the Lumber camp, the Mining Area where the Headframe that is on the National Historic Register of Historic Places is located, the Transportation Area with its Stager Depot, Victoriana with the 1980 home of composer CarrieJacobs-Bond and the 1911 St. Mary's Church and the Giovanelli home and studio.

Caspian Iron Mine - Caspian, Iron County, Michigan

Steel Headframe of the Caspian Mine

Display in the old engine house

Outdoor Mining Equipment Display

Powder Magazine

Dry House and Lamp Recharge Rack Display

Remains of the nearby Hiawatha Mine

Mining artifact display in the old Engine House

Cornish Pumping Engine

Headframe

Interior of Hoist House

Working miners display on 27th level underground